|

T-win double dust-proof slider series

Collect

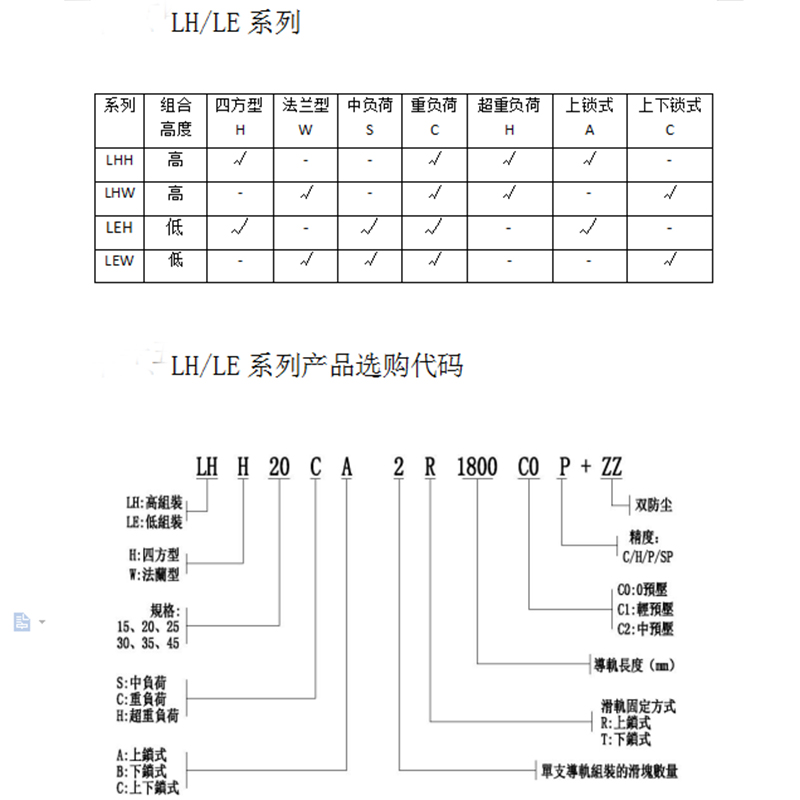

T-win double dust-proof slider series is a high dust-proof series slider developed by our company. This slider adopts multiple dust-proof, with better dust-proof effect. It is mainly suitable for woodworking machinery and some bad working environment, and it is a kind of slider with the best dust-proof effect on the market at present. It can be used for a long time in the environment with high content of wood chips, iron chips and dust without holding beads. At present, our company has various models of dust-proof slider and dust-proof technology, which can be used for reference and selection. Parameter description of double dust-proof slide block of table precision stabilizing machine: 一.Installation method In most cases, screws are used to fix the linear guide pair in the equipment, but when there is horizontal load or impact vibration, the appropriate method can be selected from the following methods according to the situation. 1. Use the fastening screw to ensure the connection between the sliding block and the guide rail and the reference plane. 2. Bolt and wedge block are used to ensure the connection between slide block and guide rail and datum plane. 3. Use the pressing plate to ensure that the sliding block and guide rail are connected with the reference plane. 4. A pin baffle is used to ensure the connection between the slide block and the guide rail and the reference plane. 二.Assembly example The assembly method and the accuracy of the assembly surface are set according to the degree of vibration and impact on the slider and the required walking accuracy. The following methods are recommended when assembling two guide rails in parallel in the same plane. 1. It has vibration and impact effect on machinery and has requirements of rigidity and accuracy. Assembly guide (1) Clean the mounting surface. (2) Place the guide rail on the installation surface stably, and pay attention to the guide rail lead side placed on the reference surface side. (3) Confirm that the installation hole of guide rail is consistent with the installation hole of reference plane, screw in the bolt but do not lock it. (4) Tighten the side retaining screws to ensure close side contact. (5) Use a torque wrench to tighten the fastening screws to the required torque until the bottom surface of the guide rail fits the reference surface closely. (6) Assemble the remaining guide rails in the same way. Installation procedure: (1) Clean the sliding block fixing surface. (2) Gently place the slider on the mounting surface, and pay attention to the side of the slider reference against the side of the mounting surface reference. Screw in screws roughly. (3) Lock the side fixing screws to fit the sliding block side closely with the installation side. (4) Use a torque wrench to tighten the slider assembly screw to the required torque, so that the slider fits tightly on the fixed surface. Note: when locking the screws, follow the diagonal sequence shown in the figure. 2. Assembly without fastening screws on the base side of guide rail Assembly reference side guide rail After the assembly bolts are tightened informally, use a small vise to firmly fix the guide rail to the side reference plane, and then use a torque wrench to lock the fixing screws in sequence with the required torque. Assembling guide rail on driven side (1) Linear block gauge assembly Adjust the linear block gauge arranged between the two guide rails to be parallel to the guide rail on the reference side according to the reading indicated by the dial indicator, and then level and fasten the guide rail on the driven side from one end according to the reading of the dial indicator with the block gauge as the reference. (2) Mobile platform method Fix the two sliding blocks on the reference side to the platform (or the special platform for measurement) and fasten the guide rails and sliding blocks on the driven side to the bed and platform informally. Calibrate the side of the passive side slider according to the dial indicator reading with bracket fixed on the platform. Start from one end of the guide rail, measure the parallelism and tighten the screws in sequence. (3) Imitating the method of reference side guide rail Place the platform on the assembled guide rail on the reference side and the sliding block of the guide rail on the driven side that is normally locked. First, fasten the two sliding blocks on the reference side and one of the sliding blocks on the driven side with bolts, while the sliding block on the other driven side is roughly fixed with bolts. Then move the platform to confirm that the rolling resistance side fixes the guide rail on the driven side in sequence. (4) Special tools method Use a specially made tool to determine the position of the guide rail on the driven side, and tighten the screws of the guide rail in sequence from one end. 3. Assembly of the side without positioning at the guide rail of the reference side Assembly of guide rail on reference side (1) Method of using false datum Use the reference side near the set guide rail assembly part of the bed, install two sliders and measuring plate tightly, fix the dial indicator on the platform to calibrate the above reference side, calibrate and fix it from one end of the guide rail. (2) Linear block gauge method Use dial indicator to calibrate the side reference plane of the guide rail on the reference side with the linear block gauge as the reference, and calibrate and fix it from one end of the guide rail. Fixation of guide rail on the driven side: the same method as that listed in the fixation without side screws on the base side of guide rail. 三.Lubrication and dust prevention The main purpose of guide rail lubrication is to reduce friction, prevent overheating and reduce wear. Lithium grease (AV2) is selected for lubrication according to load and speed in most cases, and compression grease is recommended for heavy load cases. If oil lubrication is selected, the heavy-duty guide rail should choose oil with high viscosity. If the speed is low, it is recommended to choose oil with low viscosity. Generally, 13cst is used for general speed or light load guide rail, while 68cst is used for heavy-duty guide rail. Grease life The life of grease varies with the specification, guide rail type, working conditions and other factors, and is also affected by water content, gas, grease type and other impurities, so the actual life of grease is difficult to estimate. The most common way to decide whether to supplement or replace the lubricating grease is to check the consumption of the lubricating grease. Check the loss of the sample lubricating grease with the naked eye or microscope. If the loss reaches about 10%, the lubricating grease needs to be supplemented or replaced. Under normal working conditions, the distance is about 100km or 6 months - once a year. Dustproof: generally, the standard type is used in the working environment without special requirements. If there is special dustproof requirements, please add the code (zz) after the product model 四.Installation precautions (1)When installing the guide rail and slide block, attention must be paid to the interference between the shoulder and root of the positioning side to avoid the installation accuracy deviation。

(2)Tightening torque of guide rail and slide screw kgf-cm

(3)In order to prevent dust and other foreign matters from entering into the slider through the guide screw mounting hole and affecting its accuracy and service life, the screw cover must be installed in the guide screw hole during installation。

Company:mm Come to our factory for technical exchange. We will sincerely serve you。 |