|

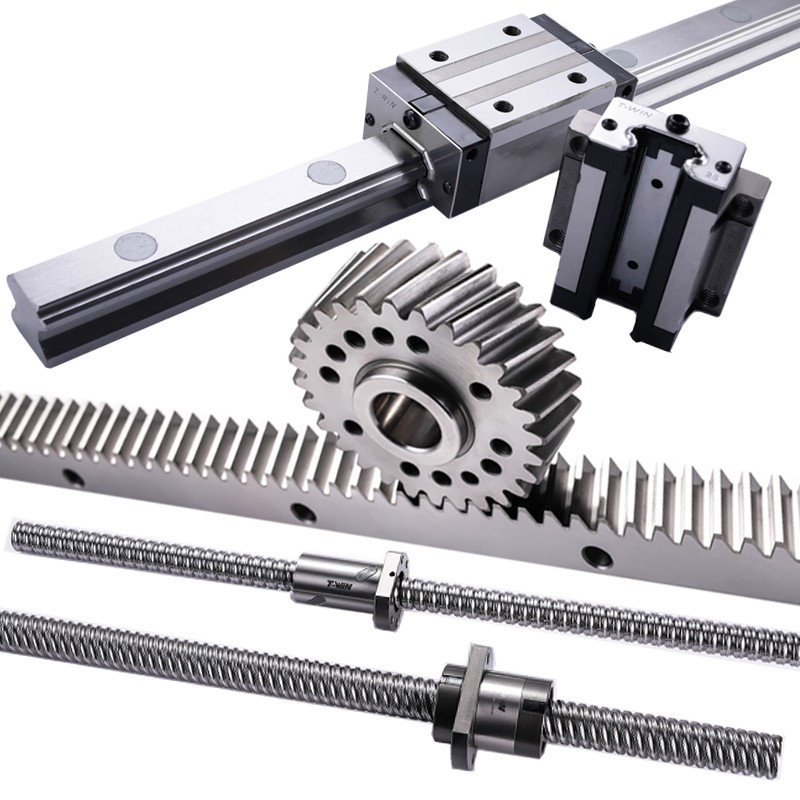

How to improve the stability of precision guide?Precision guide rail plays an indispensable role in factory processing and manufacturing. It is widely used in numerical control automation equipment. It is a high-precision transmission component. Some slight offset or jitter will cause adverse consequences to our production, so how to improve the stability of the guide rail? Please explain it to you below.

Through the selection of steel balls, the super size steel balls are installed between the guide rails to increase the movement resistance of the support, so as to solve the balance effect of PMI micro linear guide rails. In order to improve the sensitivity of the guide rail, we can reduce the resistance movement of the treatment, and correspondingly improve the movement accuracy, provided that as long as we add enough pre plus negative numbers, we can make the fixed components have a larger contact area between the moving components, so as to improve the bearing capacity of the system, not only can we expand the tolerance of the area. While ensuring the stability of the linear guide, the moving element and the fixed element of the linear guide do not use the intermediate medium, but use the rolling steel ball. Because the rolling steel ball is suitable for high-speed movement, with small friction coefficient and high sensitivity, it can meet the working requirements of the moving parts, such as the tool holder and carriage of the machine tool, etc. The basic function of the fixed element (guide rail) of the linear guide rail system is like the bearing ring, and the bracket for installing the steel ball is in the shape of "V". The bracket covers the top and both sides of the guide rail. In order to support the working parts of the machine tool, a set of linear guide rails has at least four supports. For supporting large working parts, the number of supports can be more than four. When the working parts of the machine tool move, the steel ball circulates in the bracket groove, distributing the wear of the bracket to each steel ball, thus prolonging the service life of the precision guide rail. In order to eliminate the gap between bracket and guide rail, preloading can improve the stability of guide rail system and obtain preloading. It is to install oversized steel ball between guide rail and bracket. The diameter tolerance of the steel ball is ± 20 μ m, with 0.5 μ m as the increment, the steel ball is screened and classified, and installed on the guide rail respectively. The preload depends on the force acting on the steel ball. If the force acting on the steel ball is too large, the steel ball is subjected to the preload for too long, resulting in the increase of the resistance of the support movement. |