|

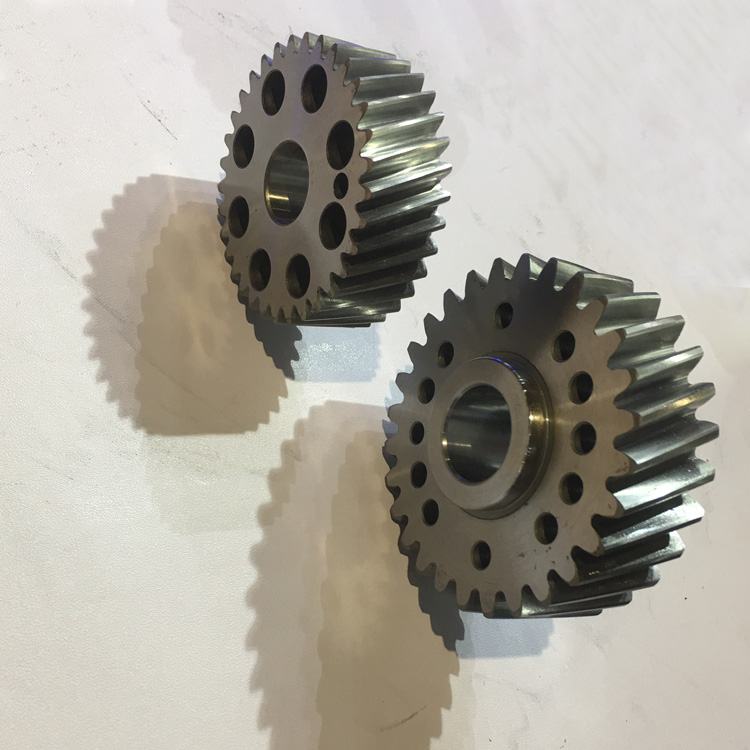

Do you know what materials are needed to make gear rack?Gear rack belongs to mechanical equipment components, which plays an indispensable role in our industrial production field, mainly bearing external force and guidance. Taiwan t-win products have the advantages of high efficiency, accurate transmission ratio, large power range and so on! It's your reliable manufacturer. Let's take you to know the commonly used materials.

The common materials of gear rack are forged steel, cast steel, cast iron, etc. Gear depends on structural dimension, material strength, load bearing, material strength, toughness, wear resistance, gear shape, complex gear accuracy, material process, common material, forged steel, cast iron, forged steel, hardness is divided into large categories, Hb is called soft tooth, Hb is called hardness, process, forging blank, normalizing, rough turning, tempering and processing, common material, simncr, liquid dynamic and static pressure bearing, common shaft shell, bearing, sealing type A new antirust technology between working procedures of precision bearing 1、 Forged steel According to the hardness of tooth surface, when HB < 350, it is called soft tooth surface H8 > 350, it is called hard tooth surface 1. Hardness of tooth surface HB < 350 Process: forging blank → normalizing -- rough turning → tempering and finishing characteristic: It has better comprehensive performance, higher strength and hardness of tooth surface, and better toughness of tooth core. After heat treatment, the cutting accuracy can reach 8 grades. Manufacturing is simple, economic, high productivity, and the requirement for accuracy is not high. 2. Hardness of tooth surface HB > 350 Process: Forging blank → normalization → rough cutting → tempering → fine cutting → high and medium collar quenching → low temperature tempering + honing or abrasive running in, electric spark running in. characteristic: High hardness of tooth surface HRC = 48-55, high contact strength, good wear resistance. The tooth core maintains the toughness after quenching and tempering, has good impact resistance and high bearing capacity. The accuracy can be reduced by half to 7 levels. Suitable for mass production, such as: automobile, machine tools and other medium speed medium load gearbox gear. When using low carbon steel: Forging blank 1 → normalization → rough cutting → tempering → fine cutting → carburizing and quenching - > low temperature tempering → gear grinding. Up to level 6 and 7. Common materials: 20Cr, 20crmti, 20mnb, 20crmnto. characteristic: Hardness of tooth surface and strong bearing capacity. The core has good toughness and impact resistance. It is suitable for high-speed, heavy load, overload drive or compact structure, locomotive main drive gear and aviation gear. 2、 Cast steel When the diameter of the gear is more than 400mm, the structure is complex and the forging is difficult, the cast steel can be used. Material 2zg45. Zg55, normalized. 3、 Cast iron It has strong resistance to scuffing and pitting, but poor impact and wear resistance. It is suitable for stable operation, low speed power or complex shape with large size. It can work under the condition of oil shortage and is suitable for open drive. 4、 Non metallic materials Cloth, wood, plastic, nylon, suitable for high speed light load. When selecting materials, it is necessary to consider the different working conditions of gears and the different failure forms of teeth, which are the basis for determining the strength calculation criteria of gears and selecting materials and heat treatment. 1. For the impact load, the material with better toughness shall be selected for the gear teeth easy to break, and low carbon steel carburizing and quenching can be selected. 2. For high-speed closed drive, the tooth surface is easy to pitting, so the material with better hardness of tooth surface should be selected, and the medium carbon steel surface quenching can be selected. 3. For low-speed medium load, when the teeth are broken, pitting and wear can occur, the materials with good comprehensive mechanical properties such as mechanical strength and tooth surface hardness should be selected, and the carbon steel can be selected for quenching, tempering and fine cutting. 4. Try to reduce the variety of materials, facilitate management, and consider resources and supply. 5. When the structural dimension is required to be compact and wear resistance is high, alloy steel shall be used. 6. Equipment and technology of the manufacturer. After reading the above, do you know the common materials and their characteristics? In the manufacturing and production of gear and rack, there will be some gears with special performance requirements. The designer must make a comprehensive analysis and comprehensive consideration according to the basic principles of material selection, and select the appropriate materials and heat treatment process. |