|

|

Precision analysis of guide rail slider for precision transmission positioning motionTime:2020-04-10 Precision linear guide rail accuracy table:

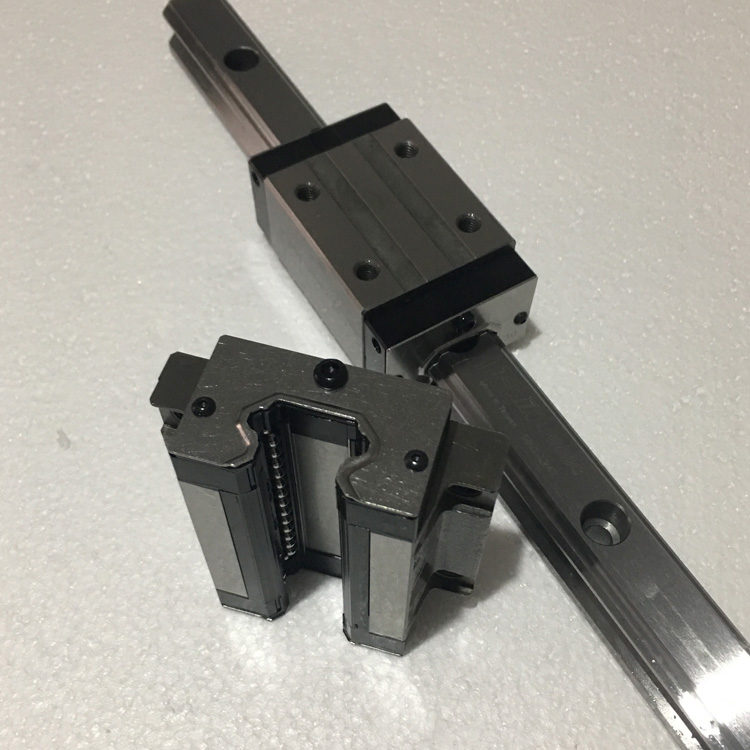

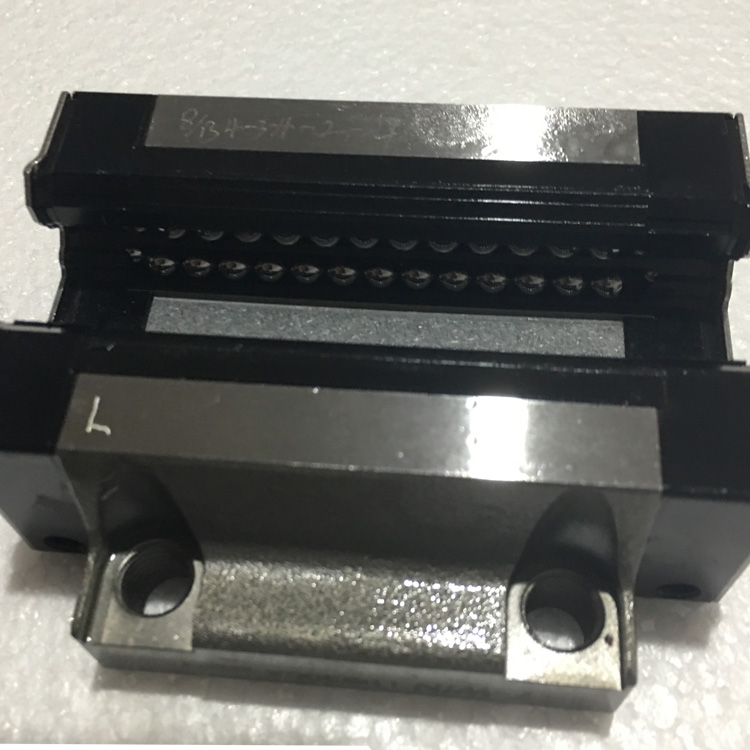

At present, the precision of precision guide rails is generally above level H, which can achieve high-precision, high-speed, and worry free operation, greatly enhancing the development of automation. 1. Under the action of preloading, the ball contacts at two points in the direction of the load, and due to minimal slip, the ball can move smoothly. 2. Due to the curvature radius of the guide rail being 52-53%, it can withstand larger rated loads. 3. Due to sufficient preload, the four row circular arc contact structure provides strong rigidity. 4. This type of circular arc contact has self-alignment, which can ensure its accuracy and rigidity even when the ball produces elastic deformation, achieving smooth motion. The high operating accuracy mainly depends on the straightness of the guide rail. The T-WIN precision machine uses a 6-meter three sided groove grinding machine for processing, so the straightness of the guide rail can be guaranteed. The accuracy of the guide rail depends on three sides and has little to do with the front side. The hardness of the linear guide rail channel can reach HRC58-62 degrees, which can meet high-speed movement without scratches. Has high wear resistance. The slider adopts dust scraper and single or double layer dust pad. Played a decisive role in dust prevention. Can be used for a long time in high dust environments with wood and aluminum shavings.

Detailed description of precision gear and rack: Focusing on precision transmission positioning motion, Taiwen Precision Machine T-WIN mainly develops and produces positioning diagonal racks. Advantages of diagonal racks: Diagonal racks have a larger contact surface than straight racks and stronger torque resistance, which can meet the characteristic of not deforming during high-speed motion. The rack has a high straightness, with an error of within 0.03 within one meter. This can meet the high-speed and high-precision operation of the equipment's transmission parts. The size of the diagonal rack is indicated by modulus, with models such as 0.5M/1M/1.5M/2M/3M/4M/5M/6M. At present, for the convenience of installation, most racks adopt a single one meter form, which ensures high accuracy and can achieve high-speed operation At present, most gears are customized based on drawings to demonstrate the process technology. The rack is of standard size. Combined use has achieved high-speed and high-precision operation. Www.t-win.com, for more information, please follow.

|

||||||||||||||||||||||||||