|

What are the correct installation steps for a linear guide rail?The installation of linear guides requires special attention from operators, as any slight deviation may affect the quality and efficiency of mechanical processing. How to install it correctly? Please see the manufacturer's detailed introduction for you.

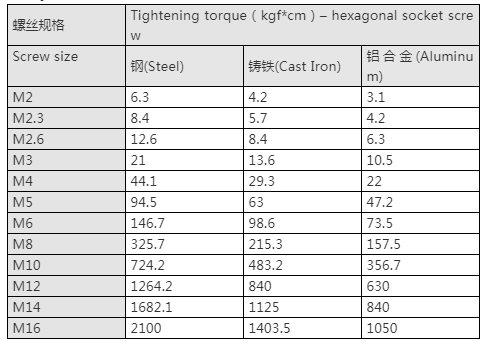

1: Before installing the linear guide rail, it is necessary to remove the burrs, dirt, and surface scratches on the mechanical installation surface. Attention: The straight slide rails are coated with rust proof oil before formal installation. Before installation, please clean the reference surface with cleaning oil. Usually, after removing the rust proof oil, the reference surface is more prone to rust. Therefore, it is recommended to apply lubricating oil with lower viscosity for the main shaft. 2: Gently place the main rail on the bed and use lateral fixing screws or other fixtures to gently fit the line rail with the lateral mounting surface. Attention: Before installation and use, it is necessary to confirm whether the screw holes match. If the machining holes on the base do not match and the bolts are forcibly locked, it will greatly affect the combination accuracy and quality of use. 3. Tighten the positioning screws of the slide rail in sequence from the center to both sides, so that the rail is slightly in contact with the vertical installation surface. Starting from the central position and tightening towards both ends in sequence can achieve relatively stable accuracy. After slightly tightening the vertical reference plane, strengthen the locking force of the lateral reference plane, so that the main rail can truly adhere to the lateral reference plane. Using a torque wrench, slowly tighten the positioning screws of the slide rail according to the locking torque of various materials. Bolt locking torque and screw specifications for linear slide rails

When installing the slide rail, please select the locking torque according to the platform material and the model of the fixing screw. Use a torque wrench to slowly tighten the slide rail bolts. 5. Install the auxiliary rails using the same installation method, and install individual sliding seats onto the main and auxiliary rails. After installing the linear slide rail on the slide seat, many accessories cannot be installed due to limited installation space, and all necessary accessories must be installed together at this stage. (Attachments may include oil nozzles, oil pipe joints, or dust prevention systems, etc.) 6: Gently place the mobile platform (table) onto the sliding seats of the main and auxiliary rails. 7: Lock the lateral forcing screws on the mobile platform first, and after installation and positioning, proceed in the following order Due to the friction mode of the guide rail being rolling friction, not only does the friction coefficient decrease to 1/50 of the sliding guide, but also the difference between dynamic and static friction becomes very small when the projector is rented out. Therefore, when the bed is running, there will be no slipping phenomenon, which can achieve μ M-level positioning accuracy. Due to the special beam structure design of the linear guide rail, it can simultaneously bear loads in the up, down, left, and right directions. Unlike the sliding guide, which can bear lighter lateral loads in the direction of parallel contact surfaces, it is easy to cause poor operating accuracy of the machine. Easy to assemble and interchangeable. When assembling, simply milling or grinding the assembly surface of the guide rail on the machine table, and fixing the guide rail and slider to the machine table with specific torque according to the recommended steps, can reproduce the high precision during processing. Traditional sliding guidance requires scraping the running track, which is both laborious and time-consuming, and once the accuracy of the machine is poor, it must be scraped again. The guide rails are interchangeable and can be replaced separately with sliders, guides, or even linear guide rail groups, allowing the machine to regain high-precision guidance. The lubrication structure is simple. If the lubrication of the sliding guide is insufficient, it will cause direct friction and wear of the contact surface metal on the bed. However, it is not easy for the sliding guide to have sufficient lubrication, and it is necessary to drill holes in appropriate positions on the bed for oil supply. The guide rail is equipped with an oil nozzle on the slider, which can be directly injected with grease using an oil gun. It can also be connected to a dedicated oil pipe joint to connect the oil supply pipe to the shearing machine for automatic lubrication. |