|

|

Introduction to the grinding process of linear slide rail manufacturers and the assembly process of slidersTime:2020-04-22 The main accuracy of linear guide rail depends on the production process of products and the progressiveness of equipment. The following is a comparison table of the accuracy of the T-WIN linear guide rail for Taiwan stability:

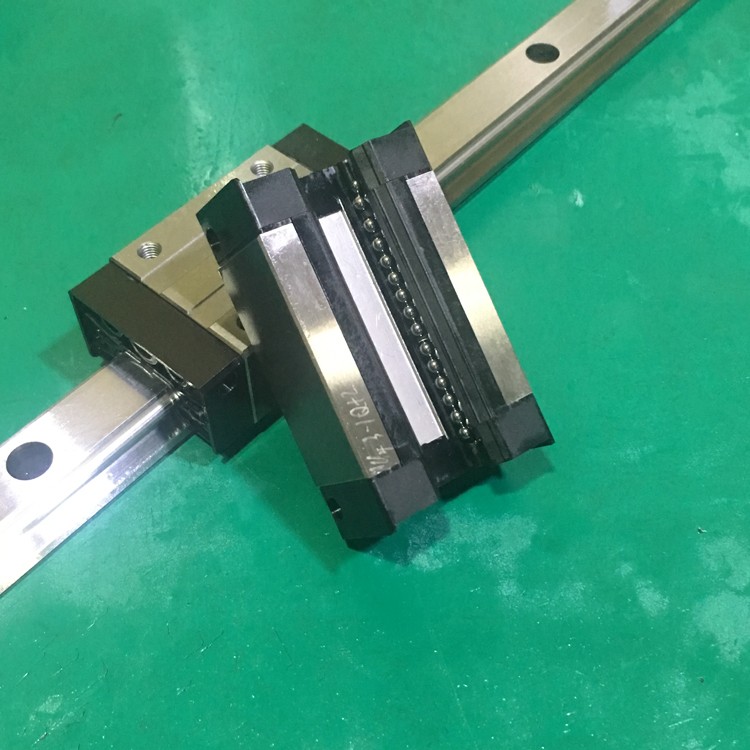

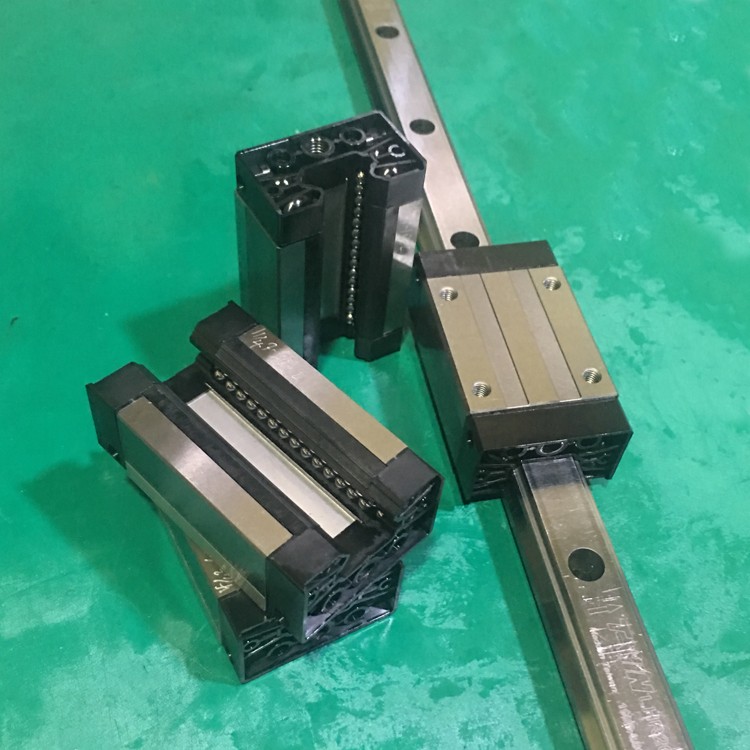

1. Under the action of preloading, the ball contacts at two points in the direction of the load, and due to minimal slip, the ball can move smoothly. 2. Due to the curvature radius of the guide rail being 52-53%, it can withstand larger rated loads. 3. Due to sufficient preload, the four row circular arc contact structure provides strong rigidity. 4. This type of circular arc contact has self-alignment, which can ensure its accuracy and rigidity even when the ball produces elastic deformation, achieving smooth motion.

The original intention of Taiwen T-WIN to provide customers with high-quality products remains unchanged, increasing investment in innovation, research and development, and production. We deeply understand that quality is the lifeblood of the enterprise, and the guarantee of quality lies in advanced production equipment, production environment, testing instruments, a sound quality assurance management system, and good human resources. The constant temperature environment of Taiwen T-WIN ensures that the temperature change within 24 hours is within 1 degree The Taiwan R&D team of Taiwen T-WIN conducts research and small-scale trial production in the Taiwan factory, and all indicators meet the design requirements before being copied to the mainland factory to ensure product stability and sustainability. To ensure the vitality of Tainan T-WIN products, Tainan T-WIN launched a second-generation standard linear slide in 2019 and developed steel belt dust-proof linear slide for industries with high dust requirements. In 2020, silent linear slide and miniature linear slide will be launched on the market.

www.t-win.com 专Be a trusted partner for customers in precision transmission, positioning, and motion. |

||||||||||||||||||||||||||