|

What are the processing methods for gears and racks?The machining of gears and racks usually uses cutting method. The cutting methods for gear teeth can be divided into two categories: copying method and generating method.

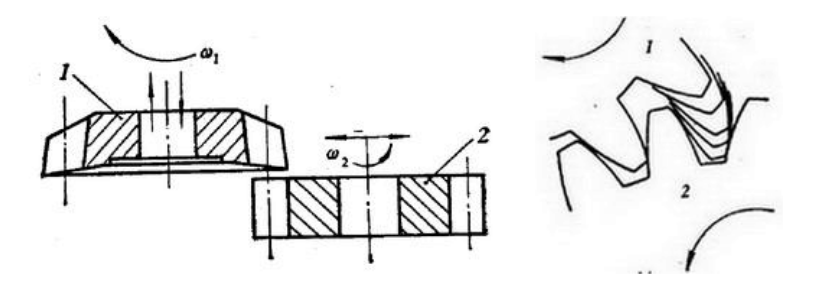

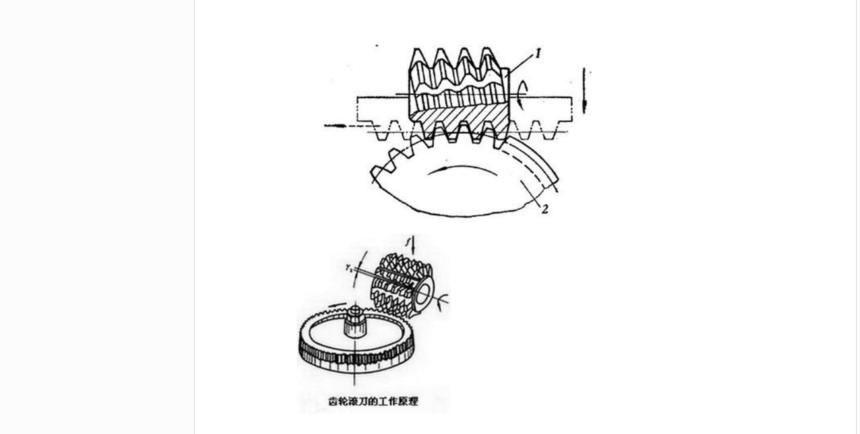

1. Copying method The profiling method is to use a disc milling cutter or finger milling cutter with the same shape as the gear tooth groove to process on a milling machine. 2. Normative method The method of generating, also known as the method of generating, utilizes the meshing principle of gears to cut the tooth profile of gears. This method has high precision in gear machining and is currently the main method for gear tooth machining. There are many types of normative methods, including gear shaping, hobbing, shaving, grinding, etc. Among them, the most commonly used are gear shaping, hobbing, and shaving And grinding teeth is used in situations where precision and smoothness requirements are high. Gear hobbing, as shown in the figure below, is the situation when machining gears with a gear hobbing cutter. Figure 1 shows the gear hobbing cutter, and Figure 2 shows the gear blank being machined. The shape of the gear cutter is similar to that of the gear, with its modulus and pressure angle being processed. The gears are the same. During machining, the gear cutter performs reciprocating cutting motion along the axis direction of the wheel blank, while the transmission system of the machine tool strictly ensures the meshing motion relationship between the gear cutter and the wheel blank. The tooth profile of the gear teeth cut in this way represents the envelope lines of the cutting edge at various positions during the relative motion of the gear cutter blade to the wheel blank, as shown in the figure (bottom right).

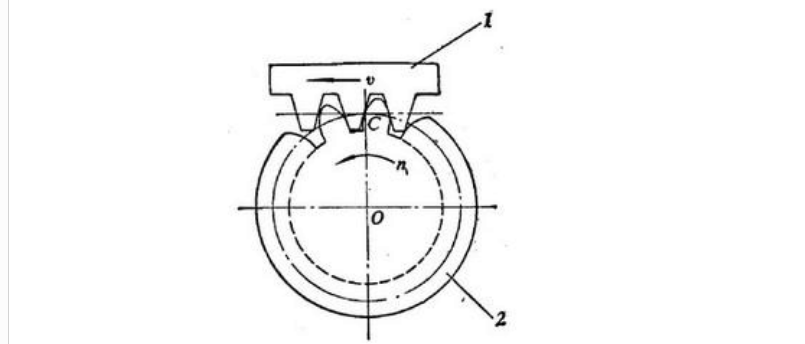

When the number of teeth of the gear cutter increases to infinity, its base circle radius becomes infinite, the tooth profile of the cutter becomes a straight tooth profile, and the gear cutter becomes a rack and pinion cutter 1, as shown in the following figure.

49/10000 实时翻译 划译 When the number of teeth of the gear cutter increases to infinity, its base circle radius becomes infinite, the tooth profile of the cutter becomes a straight tooth profile, and the gear cutter becomes a rack and pinion cutter 1, as shown in the following figure.

The shape of hob 1 is similar to a spiral with grooves along the longitudinal direction, and its axial profile has the same tooth shape as the rack. When the rolling cutter rotates At this time, it is equivalent to the hypothetical rack continuously moving in one direction, and the wheel blank is in phase 2 When the gear meshes with the rack, the hob can cut the involute tooth profile on the wheel blank according to the principle of involution. Simultaneous knife Slowly move along the axis of the wheel blank to cut out the tooth profile of the gear along the entire axial tooth width. |