|

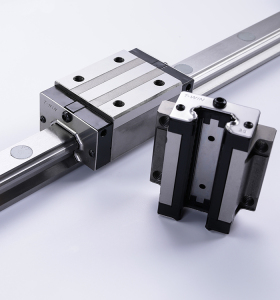

Precision guide rail docking clearanceIn order to ensure the normal operation of precision guides, appropriate gaps should be maintained between the sliding surfaces of precision guides. A small gap will increase friction, while a large gap will reduce guidance accuracy. Therefore, the clearance of precision guide rails is usually adjusted by strip steel and press.

1. Inlay strip

The insertion bar is used to adjust the side gap between the rectangular precision guide rail and the dovetail precision guide rail to ensure normal contact on the surface of the precision guide rail. The insertion strip should be placed on the side with less stress on the precision guide rail. There are two commonly used types: flat inserts and wedge-shaped inserts. It adjusts the gap by adjusting the screw to move the insert. After adjusting the gap, fix the insertion strip onto the moving precision guide rail with screws. Flat strip is easy to adjust and manufacture, but it is relatively thin and only has a few points in contact with the screw under force, making it prone to deformation and low stiffness.

The uniform contact between the moving linear guide and the static linear guide on the two surfaces of the insertion strip adjusts the longitudinal displacement separately, so the stiffness of the insertion plate is higher than that of the flat surface, but processing is a bit difficult. The adjustment method is to use adjustment screws to drive the inlay to move longitudinally to adjust the gap. The grooves on the veneer are processed after scraping. This method has a simple structure, but the gap between the protrusion of the screw head and the tooth slot will cause the tooth to move. The adjustment method is to use 5 screws to adjust from both ends to avoid panel movement, resulting in better performance. Another method is to adjust the insert through the screw and nut, and then insert a scraper into the circular hole for precision machining. This method is easy to adjust and can prevent panel movement, but the longitudinal dimension is slightly longer. 2. Pressing plate

The pressure plate is used to adjust the clearance of the auxiliary precision guide rail surface and withstand the overturning torque. This structure is used to adjust the clearance by grinding or scraping the surface. The surface of the pressure plate is separated by an empty groove. If the gap is too large, it will be ground or scraped off. If the gap is too small, it will be ground or scraped off. This method has a simple structure and is widely used, but it is difficult to adjust. Suitable for situations where adjustment is not frequent, precision guide rails have good wear resistance, or clearances have little impact on accuracy.

The gap can also be adjusted by changing the thickness of the spacer layer between the pressure plate and the connecting surface. The gasket is made up of many thin copper sheets stacked together, welded to one side with tin. This method is more convenient than scraping and grinding the pressure plate, but the adjustment is limited by the thickness of the gasket, which reduces the contact stiffness of the joint surface.

The above is about the method of gap adjustment for precision guide rails, hoping to be helpful to you! |