|

|

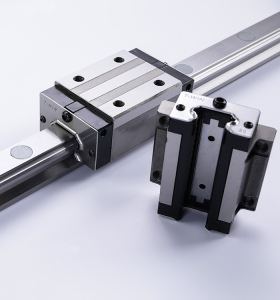

Linear guide rail manufacturers teach you how to use linear guides correctlyWith the increasing use of industrial automation equipment, people are paying more and more attention to the use of linear guides. In the use of linear guides, the size must be maintained within a certain level to ensure the accuracy of the guide. The linear guide rail manufacturer has compiled the following content, hoping to help everyone! (1) Automatic centering ability The DF (45- ° 45 °) combination from the circular groove can be absorbed by the internal sliding block of the line rail even if there is some deviation in the installation surface during installation, through the elastic deformation of the steel ball and the transfer of the contact point, resulting in automatic centering ability and high-precision stable smooth movement. (2) Interchangeability Due to strict control over production and manufacturing precision, the size of the linear guide rail can be maintained within a certain level, and the slider is designed with a retainer to prevent steel balls from falling off. Therefore, some series of precision are interchangeable. Customers can order guide rails or sliders according to their needs, or store them separately to reduce storage space.

(3) All directions have high rigidity Using a four row circular arc groove, combined with a 45 degree contact angle of four rows of steel balls, to achieve an ideal two-point contact structure for the steel balls, capable of withstanding loads from up, down, and left and right directions; When necessary, preloading can be applied to improve rigidity. (4) Excellent walking smoothness and low noise A simple and smooth steel ball reflux path design, and a steel ball circulation accessory made of impact resistant reinforced synthetic resin. Smooth operation and low voice. The above is the relevant content about linear guides compiled by linear guide manufacturers. If you have any other questions, please feel free to contact us at any time! |